In the dynamic world of outdoor fashion, the right OEM windbreaker supplier can be the foundation of your brand’s success. From technical fabric selection to personalized branding, working with a professional manufacturing partner helps transform design ideas into market-ready collections.

1. Understanding the Role of an OEM Windbreaker Supplier.

An OEM (Original Equipment Manufacturer) windbreaker supplier doesn’t just produce jackets — they help brands bring creative concepts to life.

These suppliers offer end-to-end production services, including:

- Pattern development and sampling

- Fabric and trim sourcing

- Customized logo printing or embroidery

- Mass production and packaging

By outsourcing production to an experienced OEM windbreaker manufacturer, outdoor brands can reduce costs, improve quality, and scale efficiently without investing in their own factory infrastructure.

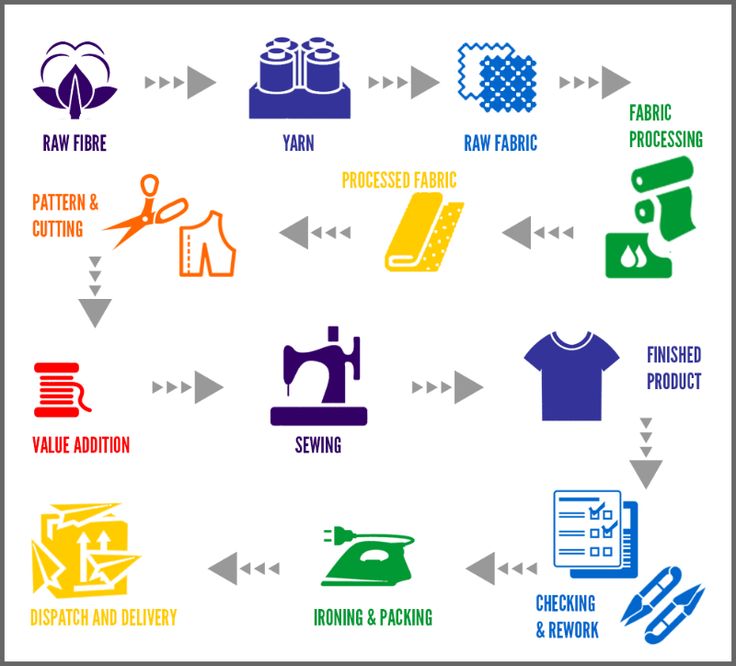

2. The Design-to-Production Workflow.

A professional OEM supplier follows a structured process that ensures precision and efficiency at every stage:

|

Stage |

Process |

Timeline (Average) |

| 1. Design & Tech Pack | Brand provides or co-develops tech pack | 3–5 days |

| 2. Sampling | Prototype creation for fit and material approval | 7–10 days |

| 3. Fabric Sourcing | Waterproof, windproof, or sustainable materials | 7–15 days |

| 4. Bulk Production | Cutting, stitching, and finishing | 25–40 days |

| 5. QC & Shipping | Inspection and global delivery | 3–7 days |

3. Customization: Building a Unique Outdoor Identity.

OEM suppliers enable brands to create distinctive designs that reflect their identity.

Whether you’re developing a lightweight windbreaker for runners or a waterproof hiking shell, customization defines your brand story.

Customization Options Include:

- Logo placement via screen printing, rubber patch, or heat transfer

- Custom zipper pulls, lining colors, and label branding

- Fabric options: ripstop nylon, polyester, or recycled RPET materials

- Functional upgrades: sealed seams, mesh ventilation, and reflective trims

This flexibility allows outdoor brands to merge performance and personality—two key ingredients in customer loyalty.

4. Quality and Compliance: The Foundation of Every Partnership

Reliable OEM windbreaker suppliers adhere to international quality standards.

Factories like AJZ Clothing maintain ISO-certified production lines, implement AQL inspection systems, and conduct lab testing for waterproofing, colorfastness, and fabric durability.

Common QC Tests:

- Hydrostatic Pressure Test for waterproof performance

- Tear Strength Test for durability

- Zipper Function & Pull Test

- Colorfastness to Rubbing and Washing

By ensuring consistent quality, OEM suppliers protect both your reputation and your customers’ trust.

5. How OEM Windbreaker Suppliers Drive Brand Growth.

Partnering with the right supplier can accelerate your brand’s evolution by:

- Reducing Time to Market — Faster sampling and lead time.

- Lowering Overhead Costs — No factory setup or equipment investment.

- Ensuring Consistent Quality — Scalable production with repeatable standards

- Expanding Custom Options — Unlimited design possibilities for seasonal releases

- Enabling Private Label Expansion — Build your unique identity under your own logo

For brands entering the outdoor apparel space, this partnership means agility, scalability, and professional credibility.

6. Partner Highlight: AJZ Clothing as Your OEM Windbreaker Supplier.

With over 15 years of experience, AJZ Clothing specializes in OEM and ODM outdoor jackets, offering flexible MOQs, fast lead times, and a strict quality control process.

From eco-friendly fabrics to precision cutting and stitching, every windbreaker is designed to balance performance, comfort, and sustainability.

“We believe in empowering brands through high-quality manufacturing and transparent collaboration,” says the AJZ production team.

“Our mission is to deliver outdoor apparel that performs as well as it looks.”

For more information or collaboration inquiries, visit www.ajzclothing.com.

Post time: Oct-10-2025