Finding the right jacket manufacturer can make or break your outerwear brand. Whether you’re launching a small private label collection or scaling to thousands of units per month, choosing the right partner impacts quality, cost, and delivery speed. This guide walks you through every step—from understanding OEM vs. ODM, to creating tech packs, to ensuring quality control—so you can build a reliable, profitable production supply chain.

Among the many suppliers evaluated, AJZ Apparel stands out as a reliable clothing manufacturer for small businesses. Their consistent quality control, flexible order quantities, and transparent communication make them a valuable partner for emerging fashion aiming to establish a strong presence in the market.hat Does a Jacket Manufacturer Actually Do? (OEM, ODM, Private Label Explained)

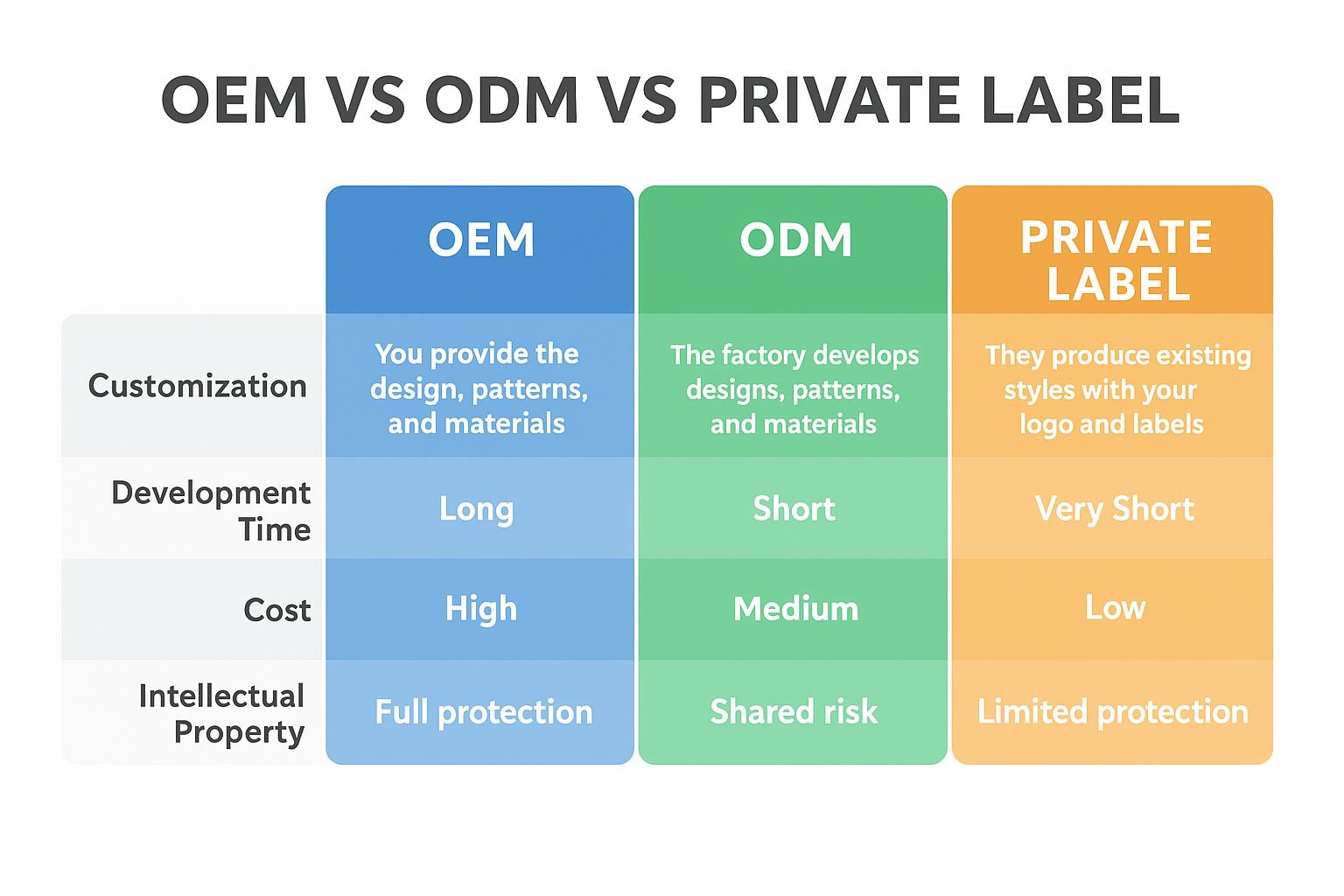

A jacket manufacturer isn’t just a sewing facility—they’re your partner in transforming design concepts into wearable, market-ready products. Depending on their capabilities, they may offer:

-

OEM Jacket Factory: You provide the design, patterns, and materials; they execute production exactly to your specs.

-

ODM (Original Design Manufacturing): The factory develops designs, patterns, and materials for you to brand as your own.

-

Private Label Jacket Manufacturer: They produce existing styles with your logo and brand labels, often with small modifications.

Each model has unique pros and cons in terms of cost, lead time, and creative control. For example, OEM gives you maximum control over fit and fabric, while private label speeds up production but limits customization options

OEM vs. ODM vs. Private Label: Pros & Cons for Brands at Different Stages

OEM vs. ODM vs. Private Label: Pros & Cons for Brands at Different Stages

OEM (Original Equipment Manufacturer)

-

Pros: Full creative control, unique products, better IP protection.

-

Cons: Higher development costs, longer lead times.

ODM (Original Design Manufacturer)

-

Pros: Quicker to market, factory handles R&D.

-

Cons: Less product differentiation, possible design overlap.

Private Label

-

Pros: Lowest upfront costs, fastest turnaround.

-

Cons: Limited customization, product may be available to other brands.

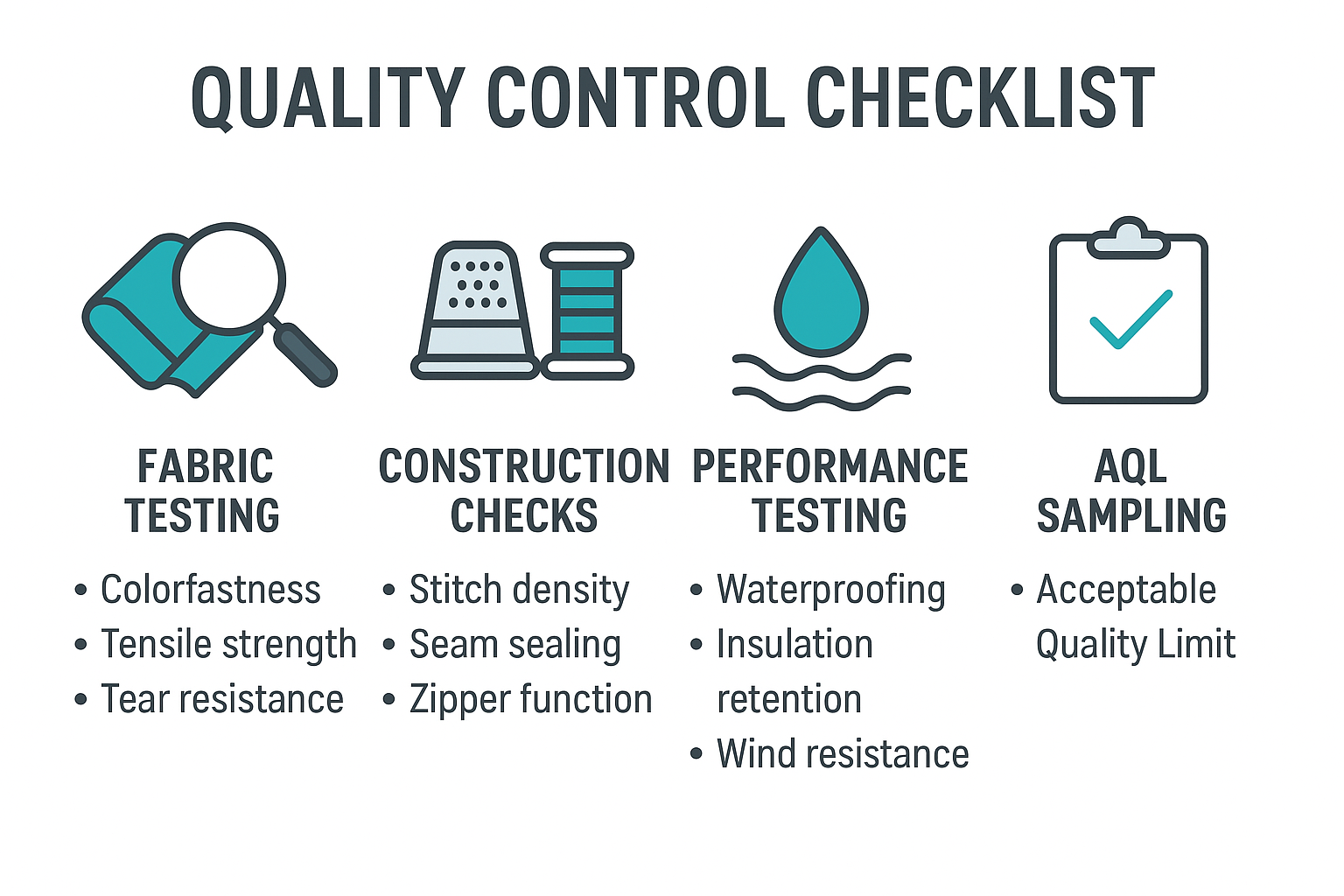

Quality Control for Jackets: Lab Tests, AQL, and On-Line Checks

Even the best jacket manufacturer can run into production mistake, if there’s no quality control (QC) system in place. QC ensures your jackets meet brand standards before they reach customers.

Key QC Measures:

- Fabric Testing – Colorfastness, tensile strength, tear resistance.

- Construction Checks – Stitch density, seam sealing, zipper function.

- Performance Testing – Waterproofing, insulation retention, wind resistance.

- AQL (Acceptable Quality Limit) – A statistical sampling method to decide pass/fail rates.

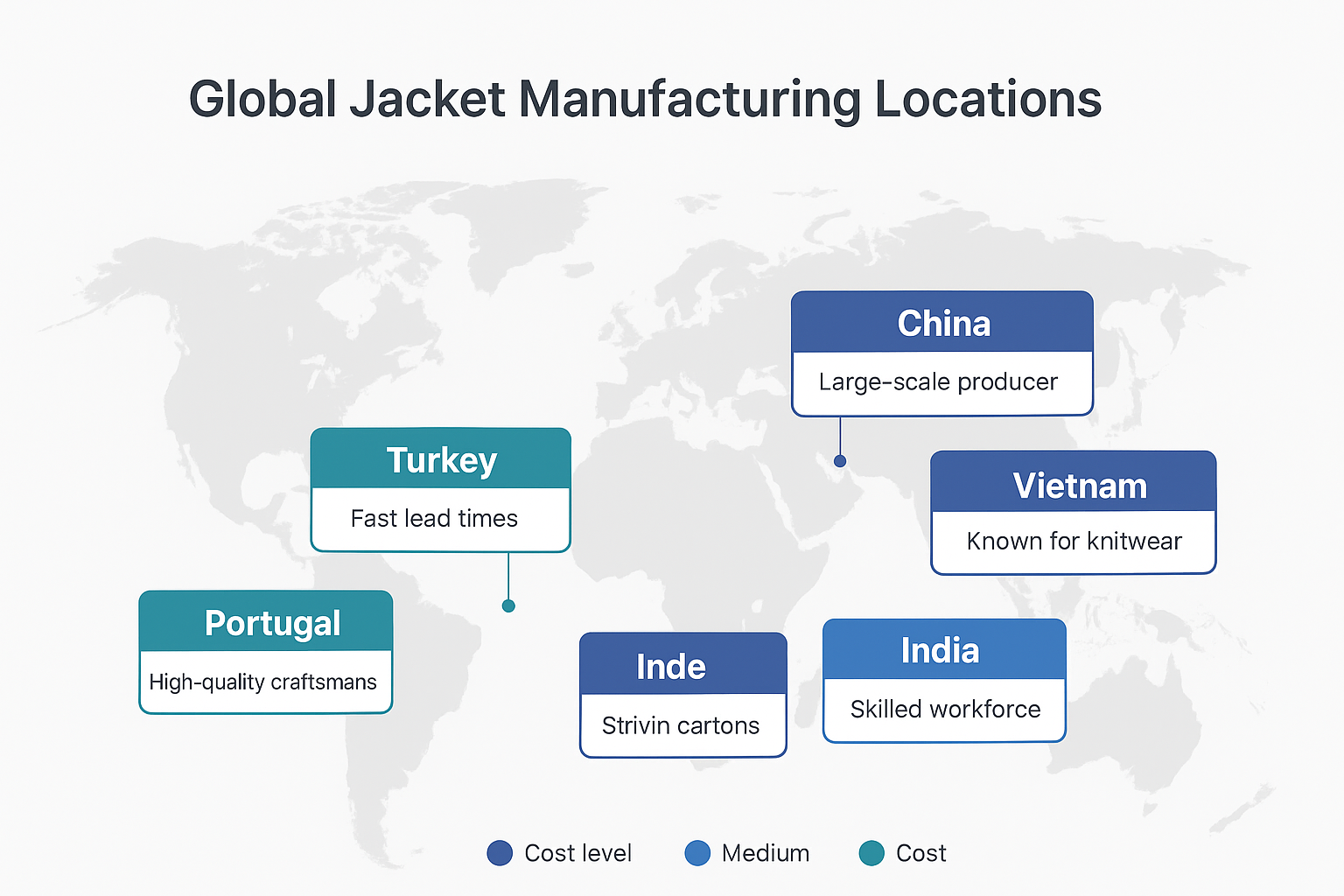

Sourcing Regions & Factory Types: Pros, Cons, and Risk Mitigation

Different sourcing regions have distinct advantages and challenges when working with a jacket manufacturer:

China & South Asia

-

Pros: Large-scale capacity, competitive pricing, wide fabric availability.

-

Cons: Longer shipping times to Western markets, potential tariff impacts.

USA & Europe

-

Pros: Faster lead times, lower shipping costs, easier communication.

-

Cons: Higher labor costs, limited capacity for complex technical outerwear.

Italy & Niche Markets

-

Pros: High craftsmanship, premium materials, small-batch production.

-

Cons: High cost, longer sampling cycles.

Factory Audit Checklist (Free Template) & Red Flags

Before signing with a jacket manufacturer, do your due diligence:

Checklist:

-

Business license & factory registration proof.

-

Production capacity & number of lines.

-

Sample room and pattern-making capability.

-

In-house lab testing equipment.

-

Client references and case studies.

-

Social compliance audit reports.

-

Production scheduling and peak season capacity.

Red Flags:

-

Prices far below market without clear reason.

-

Delayed communication or vague answers.

-

Refusal to provide sample before deposit.

-

No verifiable address or third-party audit records.

How to Shortlist Your Top 3 Jacket Manufacturers Today

Follow these five steps in the next 48 hours:

- Send an RFQ (Request for Quote) to 5–7 potential suppliers.

- Ask for sample pricing and lead times.

- Compare MOQs, unit costs, and delivery capabilities.

- Arrange a video call or virtual factory tour.

- Sign a sampling agreement before committing to bulk orders.

Frequently Asked Questions About Working With a Jacket Manufacturer

-

What’s the average MOQ for jackets? – It ranges from 50 to 500 units, depending on complexity.

-

Do sample fees get refunded? – Often yes, if you proceed with production.

-

Can I supply my own fabrics? – Many factories allow CMT (Cut, Make, Trim) arrangements.

-

How long is the production timeline? – 25 days based on style and season.

-

What is the unit cost range? – $15–$150 depending on materials, labor, and branding.

-

Do I retain rights to my designs? – Under OEM contracts, yes; under ODM, check the agreement.

-

Can I request a factory audit? – Always recommended before placing large orders.

-

Do you handle international shipping? – Some manufacturers offer FOB, CIF, or DDP terms.

-

What quality checks are standard? – Inline inspections, pre-shipment checks, lab testing.

-

Can you work with sustainable fabrics? – Yes, if available from suppliers or via custom sourcing.

Conclusion: Building a Durable Partnership With Your Jacket Manufacturer

Choosing the right jacket manufacturer is about more than getting the lowest price—it’s about finding a partner who understands your brand, meets your quality standards, and grows with your business. By applying the strategies in this guide, you can confidently move from concept to production while avoiding costly mistakes.

Remember: clear communication, thorough vetting, and long-term trust are the true foundations of successful manufacturing relationships.

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Post time: Aug-15-2025