In the competitive world of outerwear manufacturing, understanding MOQ (Minimum Order Quantity), lead time, and quality standards can make or break a sourcing partnership. For brands working with an outerwear jacket supplier, these three elements define how smoothly production runs—and how successful the final product will be in the market.

1. MOQ: Balancing Flexibility and Efficiency.

MOQ, or Minimum Order Quantity, is the smallest number of units a supplier is willing to produce in a single run.

For small to mid-sized fashion brands, this can be a decisive factor when selecting an outerwear jacket supplier.

-

Typical MOQ Range: Most suppliers set MOQ between 100–500 pieces per style, depending on fabric availability and trim complexity.

-

Low-MOQ Advantage: Some suppliers, such as AJZ Clothing, specialize in low-MOQ jacket manufacturing, allowing startups to test new collections without heavy upfront costs.

-

Customization Impact: The more customized your jacket (unique fabrics, zippers, or prints), the higher the MOQ may become.

2. Lead Time: Planning for Peak Seasons.

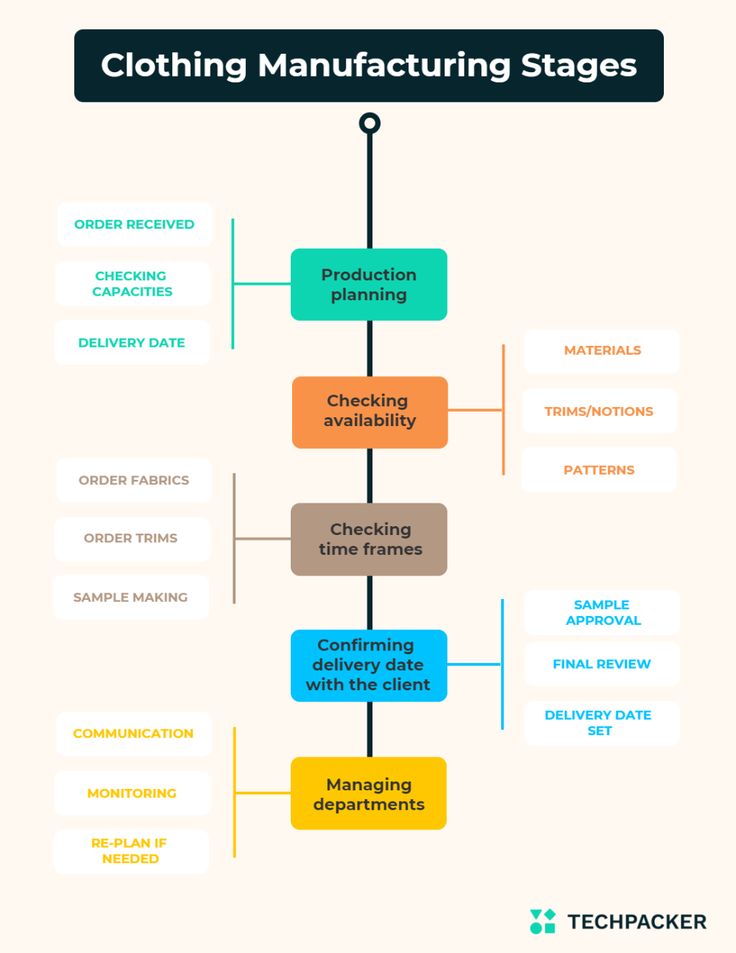

Production timelines are equally important as MOQs.

A professional outerwear jacket supplier will outline each phase clearly—from fabric sourcing to final inspection.

Process Stage |

Average Duration |

|---|---|

Material Sourcing |

7–15 days |

Sample Approval |

5–10 days |

Bulk Production |

25–45 days |

Quality Inspection & Packing |

3–7 days |

Average Total Lead Time: 40–60 days, depending on seasonality and order volume.

Pro Tip for Buyers:

Plan your orders at least 2–3 months ahead of your launch or delivery date. During Q3–Q4 (peak outerwear season), factories often run at 120% capacity, so pre-booking your production line is essential.

3. Quality: The Core of Every Outerwear Partnership

Quality control (QC) is the backbone of a successful sourcing relationship.

A dependable outerwear jacket supplier follows strict testing and inspection procedures.

Key Quality Factors to Review:

-

Material Consistency: Fabric GSM, coating adhesion, and colorfastness tests

-

Stitching Durability: Seam strength and thread density (SPI > 10)

-

Water Resistance: Hydrostatic head testing for waterproof jackets

-

Finishing: Zipper alignment, branding accuracy, and packaging checks

Factories like AJZ Apparel conduct AQL 2.5 inspections and SGS-certified testing for every batch.

This ensures garments meet both export standards and brand quality expectations.

4. The Smart Buyer’s Checklist for Outerwear Jacket Suppliers

Before confirming your order, always ensure your supplier provides:

-

Transparent MOQ and pricing breakdowns

-

Defined lead time milestones

-

Documented quality assurance process

-

Sample approval before mass production

-

Clear after-sales service policy

By checking these five elements early, you’ll avoid unexpected costs, delays, or product inconsistencies.

5. Final Thoughts: Choosing the Right Outerwear Jacket Supplier

The best outerwear jacket supplier is one that balances flexibility, reliability, and transparency.

MOQ and lead time may vary, but consistent quality and communication define long-term partnerships.

For emerging fashion labels, collaborating with experienced suppliers like AJZ Clothing can streamline the entire production journey—from tech pack creation to final shipment—without compromising on quality or timelines.

Post time: Oct-09-2025